A tough, flexible cable for powering portable equipment, SOOW cable (which is often shortened to SO, as in SO cord, SO wire or SO cable) is the kind of cable you're likely to see running across a garage floor, machine shop or work site.

SOOW is one option of many in the Portable Cord category, which also includes bus drop, festoon, jumper, welding, and other service cord types such as SJOOW and SEOOW/STOOW.

SOOW is the most commonly used, and like much of the category, it's essentially a type of extension cord, relied on for its ability to take a beating. Step on it, drag it, get it wet, leave it out in the cold... SO cord don't care. It's designed to be used in rough environments, whenever and wherever power is needed, in temperatures ranging from at least -40°C (-40°F) to 90°C(194°F). SOOW also happens to be flame-retardant.

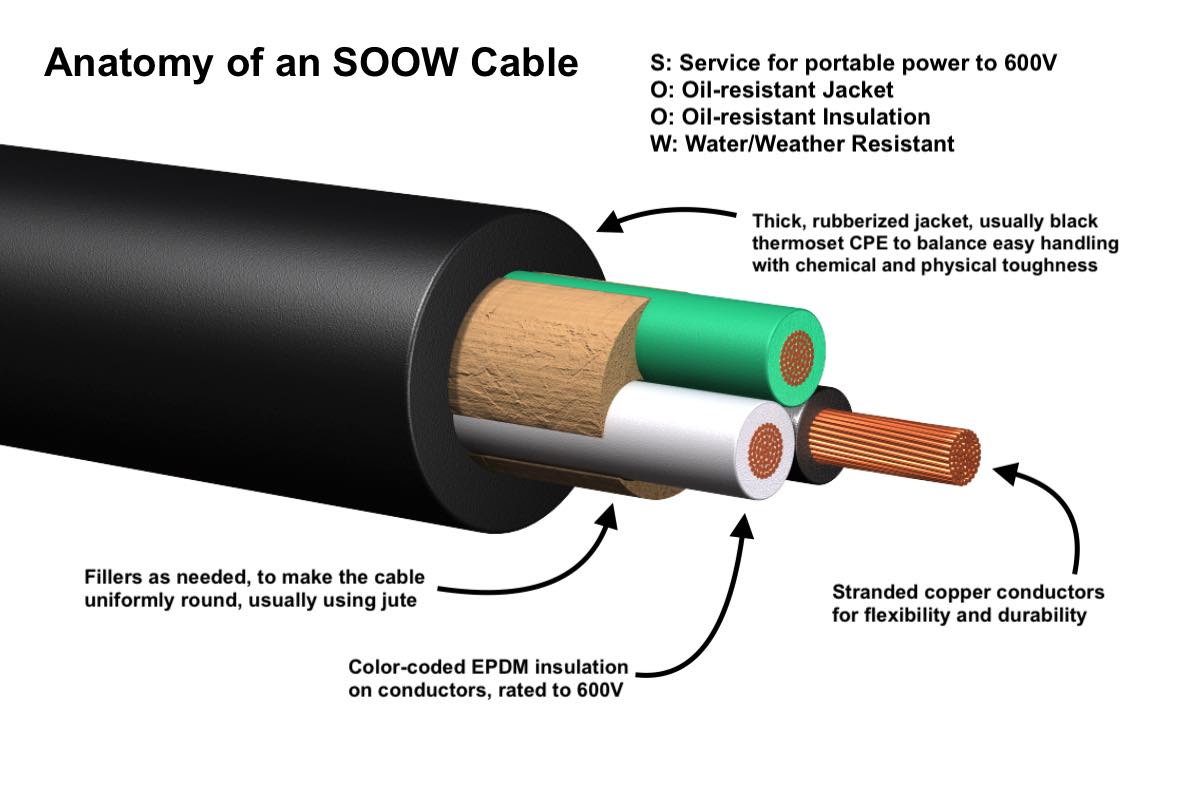

What does SOOW stand for?

S: Service

These cables are rated to supply electrical power, up to 600 volts. The term "cord" is also associated with SO, indicating they are typically used for temporary power, as opposed to permanent installations. However, they are rated for use as wiring in industrial machinery and appliances.

OO: Oil-Resistant Jacket and Insulation

Both the outer layer (jacket) and the inner layers that protect the conductors (insulation) are safe to use in environments where they may be exposed to oil. That's a necessary feature in most any setting where machinery (lubricated with oil) is in use, or being repaired, or other solvents and chemicals are used.

W: Water/Weather-Resistant

While they can be submerged in water, and are both ozone and UV-resistant, SOOW cables are not recommended for permanent installation underwater or in direct sunlight. SOOW is also not rated for direct burial, even if only temporarily.

What are SOOW cables made of?

SOOW materials and construction strike a balance between toughness, durability and flexibility. Let's start from the inside out.

Stranded Copper Conductors

Because they are designed for ease of handling and repeated flexing, SOOW conductors are made of stranded copper, meaning many smaller wires are twisted together to form each conductor. A single 10 AWG conductor, for example, is typically made of 104 tiny 30 AWG wires, making conductors behave more like ropes, so they lie flat and do not retain a bend unless severely kinked or crushed.

SOOW conductors are most often bare copper, which has been fully annealed, meaning softened for maximum flexibility. Tinned copper conductors are also common, providing added protection against corrosion and oxidation in wet environments.

EPDM Insulation

Each conductor is insulated with a synthetic rubber, EPDM, short for Ethylene Propylene Diene Monomer, a compounded elastomer. As the name implies, EPDM is somewhat "elastic," and can regain it's shape after being stretched. It has properties of both a polymer (a plastic) and a rubber, making it a good insulator, but also tough, flexible, temperature-resistant and oil-resistant.

Fillers

Because SOOW cables are designed for easy handling, roundness is key. Cables with low conductor counts would be lumpy and bumpy, if not for fillers that fit between the conductors, to create a rounded bundle and a nice, smooth cord that easily bends and lays flat in any direction.

CPE Jacket

Thermoset Chlorinated Polyethylene (CPE) is typical for SOOW cables due to it's soft, rubbery characteristics. Heat-cured when applied to the cable, thermoset CPE forms cross-linked chemical bonds, making them stronger, and more resistant to heat and chemicals, compared to thermoplastics. SOOW jackets are almost always black, except for select offerings like Carol Brand's Super Vu-Tron line of portable cords which are considered a premium product with higher temperature ratings and added toughness.

SOOW Sizes and Configurations

Ranging in size from the smallest 18 AWG conductor, up to 2 AWG, SOOW covers a broad set of applications. Conductor counts also vary widely from a single conductor up to 40! Yes, a 16 AWG, 40 conductor cable is over one inch in diameter and weighs close to a pound per foot.

The most common SOOW sizes and configurations usually include fewer conductors, since they are used as a power supply for one piece of equipment: 18AWG/3C, 12AWG/3C, 10AWG/3C, 6AWG/4C and 4AWG/4C.

SOOW conductors usually follow the color code convention: black, white, green, red, orange, light blue, repeating with a black stripe, then a red stripe. If the conductor count is over 21, the color scheme starts over with black.

Does SOOW cable have a shield?

Shielding is not typical for SOOW cords. They are made with shields, though stock can sometimes be harder to find. When an application requires limiting electromagnetic interference (EMI), if the cord is used near sensitive electronics, for example, a shield ensures there isn't any "leakage," by wrapping conductors in a mesh or foil.

Why is SOOW cable often not UL listed?

SOOW cables are made to conform with UL Flexible Cord Subject 62 and CSA Flexible Cord C22.2-49. However, most cables on the market are not listed by Underwriters Laboratories, Inc. (UL). This may seem unusual, but it happens to be an accepted industry practice. UL-listed cables can be found, but they are in lower demand, tend to be more expensive, and it's not uncommon for them to be less flexible and even thicker than their non-UL counterparts, sometimes requiring different connectors.

Even though many SOOW cables cannot claim they meet UL standards, most do claim MSHA approval and RoHS compliance. If your application requires a UL-listed SOOW cable, we can help you find it through one of our suppliers, but you may also consider a different cable style, where UL-listing is more common.

Who manufactures SOOW cable?

All SOOW we carry is made in the USA. Most options we carry are considered generic and fully interchangeable, meaning it's a commodity product that differs very little among manufacturers. A number of US manufacturers make SOOW, including Priority Wire, General Cable, Southwire, Coleman, Americord and Cerrowire.

Check out our full line of SOOW Cable here.